Machine control, or numerical control, also known as computer numerical control (CNC), is the automated control of machining tools (drills, boring tools, and lathes) by means of coded programmed instruction. Once the coded program instructions are loaded, a CNC machine can process the material to specification without an operator.

Tektronix started machine controls in the late 1960s by designing equipment for its own internal use. Existing controllers available were very large with tube circuitry, drifted, and were hard to maintain.

The Tektronix controller was a TTL (transistor transistor logic) digital controller. It was basically a discrete logic state machine. Math functions such as circular interpolation were all designed in digital circuits. It was small, accurate and reliable. Tektronix used these controllers in the model shop as well as in CRT for mesh spot welding. This October 3, 1969 TekWeek features the use of machine control in the model shop. Click on the image to view the PDF.

Tektronix also developed a tape verification product that the programmer used to create the program. The resulting program was punched onto a paper tape and the accuracy was checked by running the tape and viewing the tool path on a Type 611 display. The results were a superb system and a new market for Tektronix opened up.

This October 16, 1970 TekWeek article describes the reception of the 1701 at the Production Engineering Show.

This January 8, 1971 TekWeek features the introduction of the 1701 and 1702 numeric control systems. Click on the image to view the PDF.

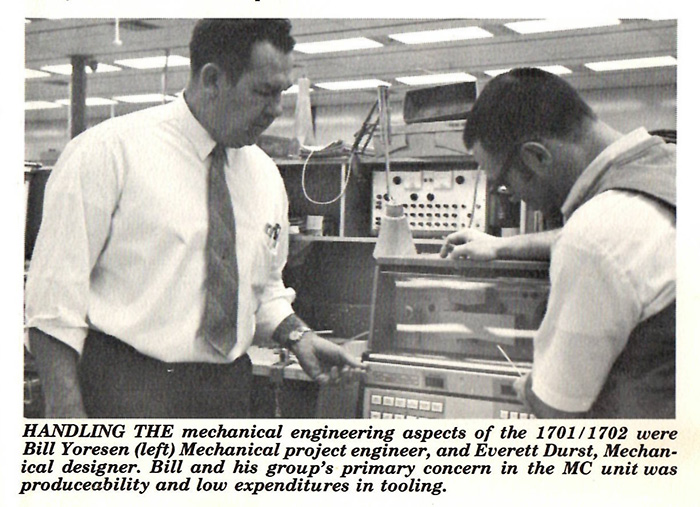

This January 15, 1971 TekWeek features two of the mechanical team.

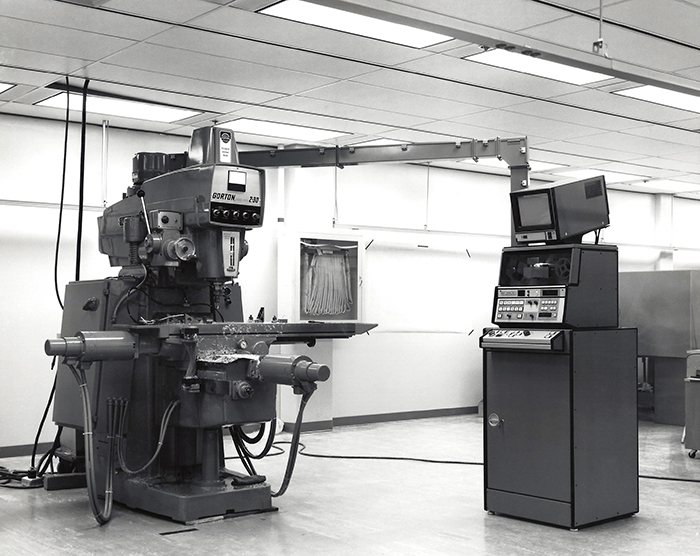

These three photos of a 1701 Machine Control Unit interfaced to a Gorton 2-30 tracer mill are labeled "Machine Control Show Booth” and dated March 1, 1971.

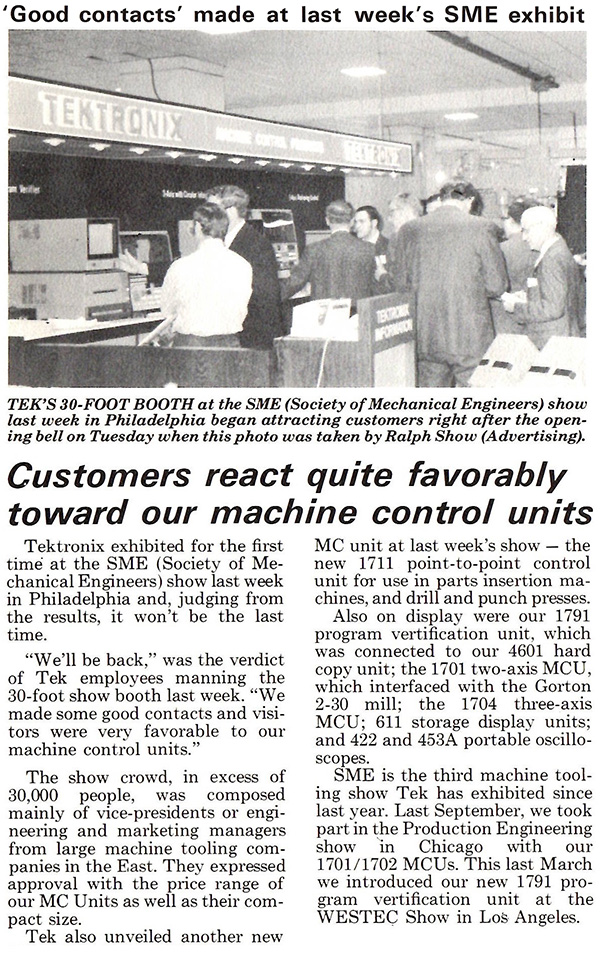

This May 7, 1971 TekWeek features the introduction of the 1711 point-to-point control unit.

This undated photo shows Les Wold in the model shop along with a machine control unit.

This excerpt is from the 1971 Tektronix Catalog. Click on the image to view the PDF.

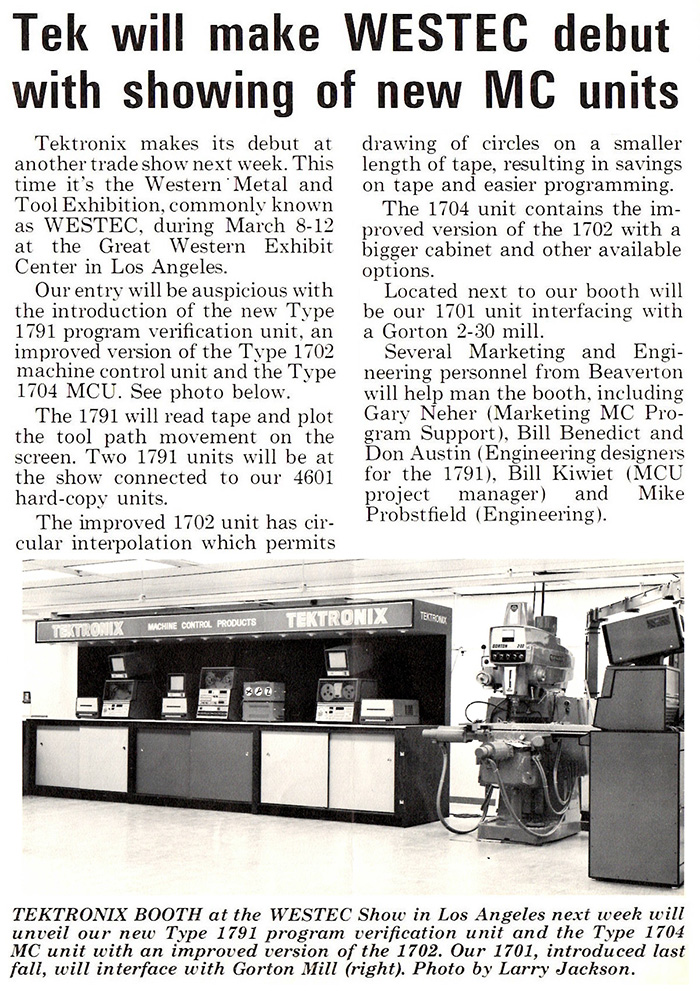

This March 5, 1971 TekWeek features the introduction of the 1704 Machine Control Unit and 1791 Program Verification Unit at the Western Metal and Tool Exhibition.

The October 15, 1971 Tekweek features a report by Bill Walker at an Area Rep meeting. This excerpt mentions diversification efforts by the company including machine control.

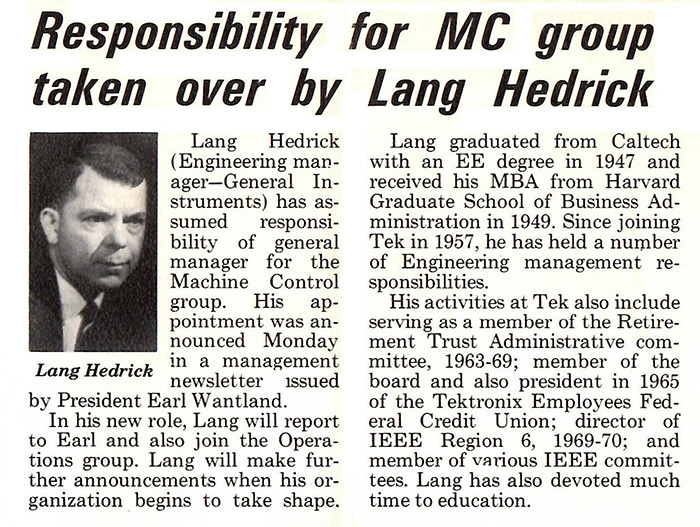

This November 18, 1971 TekWeek article announces Lang Hedrick as the new Machine Control manager.

This December 1971 brochure features the 1791 Program Verifier. Click on the image to view the PDF.

This January 28, 1972 TekWeek/TekTalk describes how numeric control in the Model Shop significantly speeds up fabrication. Click on the image to view the PDF.

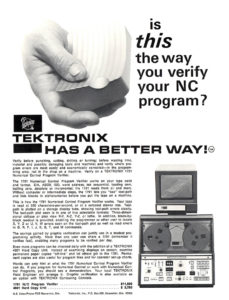

These next two ads also features the 1791 Program Verifier. This ad is from March 1972. Click on the image to view the PDF.

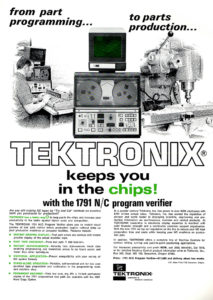

This ad is from May 1972. Click on the image to view the PDF.

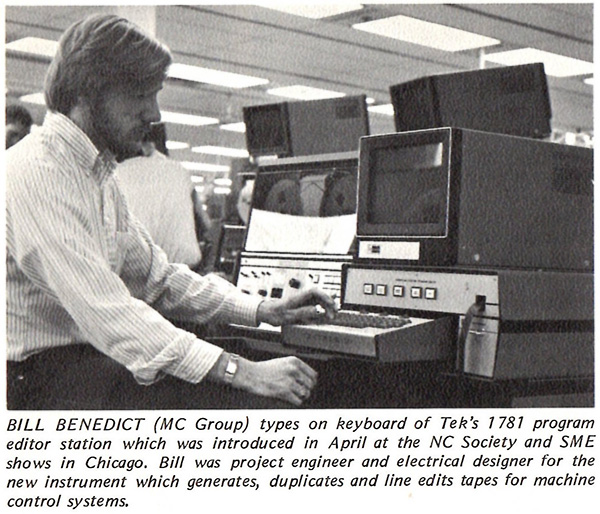

This June 2, 1972 TekWeek article features the 1781 Program Editor Station.

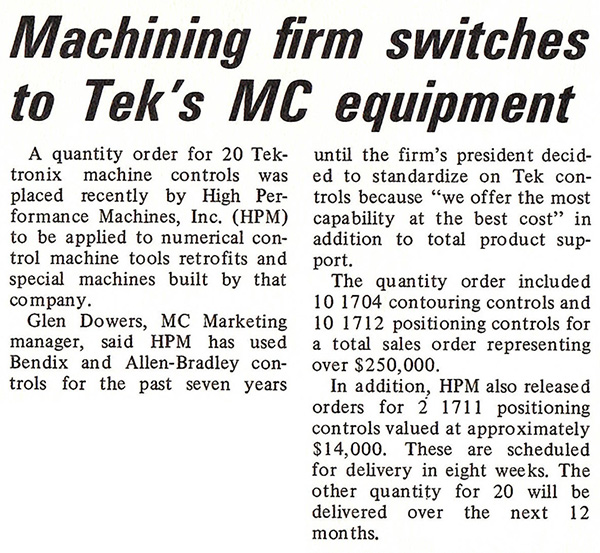

This June 23, 1972 TekWeek article features a sale of 20 machine control units.

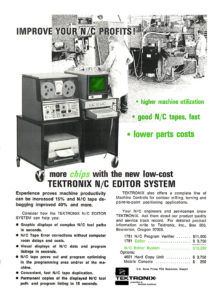

This ad is from August 1972. Click on the image to view the PDF.

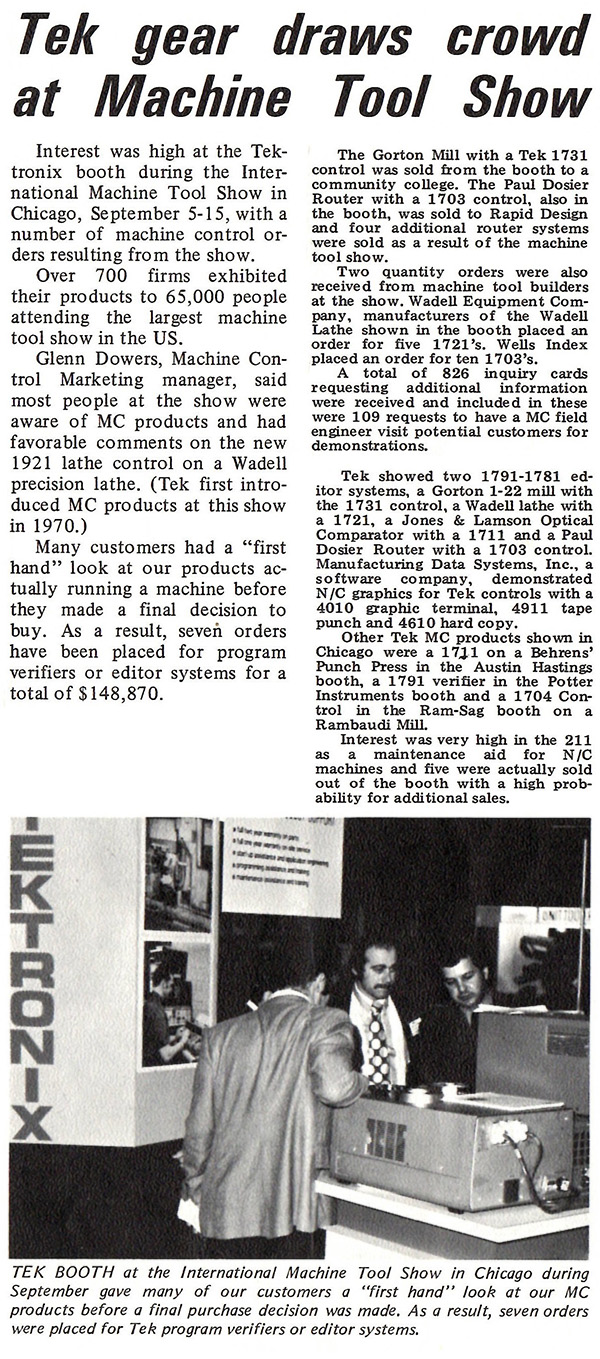

This October 20, 1972 TekWeek article describes the booth at the International Machine Tool show.

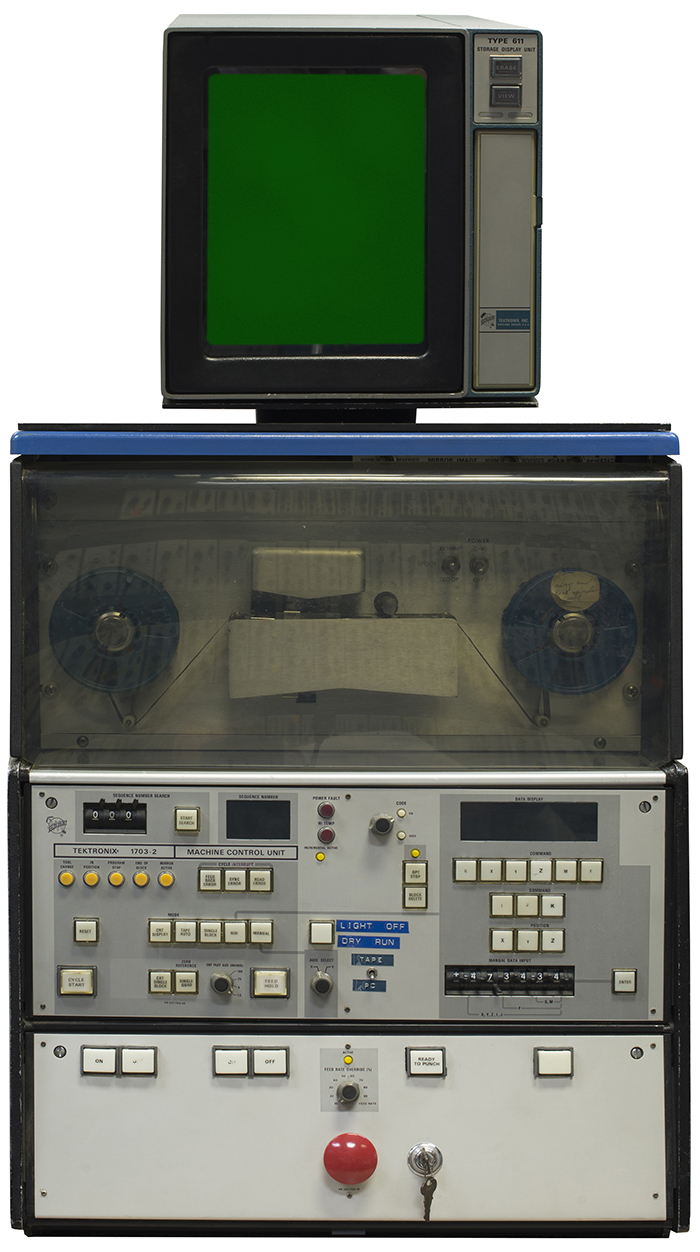

The museum has a 1703-2 machine control unit on display. It consists of a 611 Storage Display Unit, a paper tape reader, and the machine control unit.

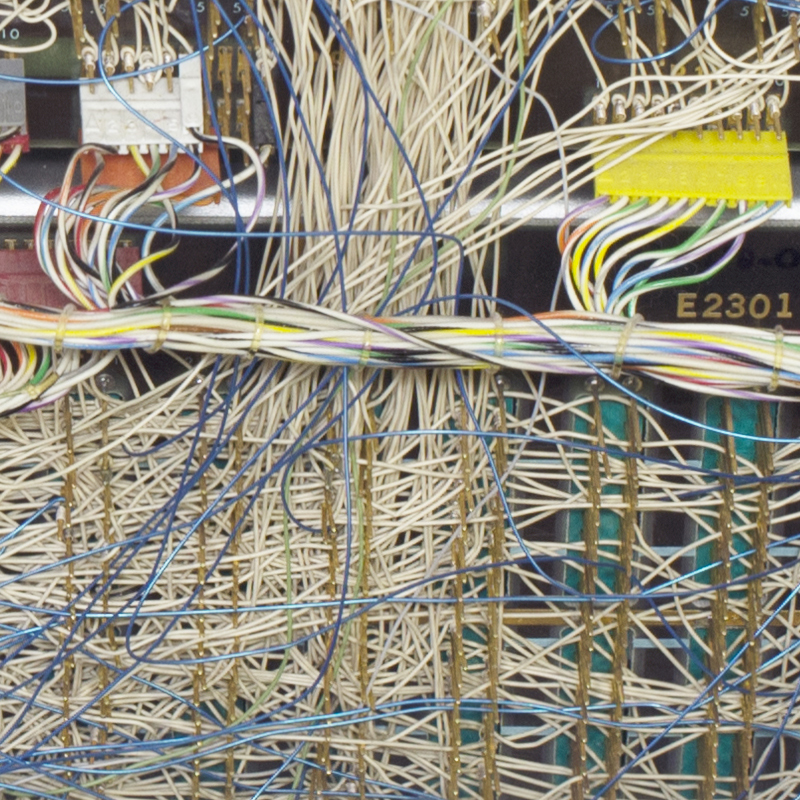

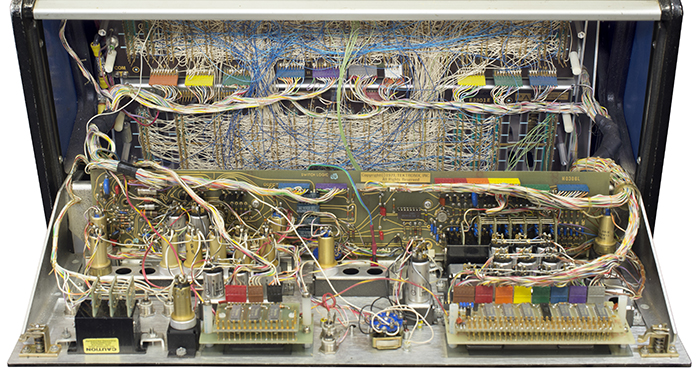

The construction is a number of smaller PCBs inserted into a backplane which is hand wire-wrapped.

Here is a closer view of the backplane hand wire-wrapping.