We have a display case for a small collection of Tektronix cathode ray tubes - CRTs, CRT components and memorabilia which spans the history of CRT development and production at Tektronix from start to finish. There also is a story board with pictures documenting Tektronix CRT operation and some of it people and products. In addition, we have a collection of Tektronix CRT patents.

Tektronix has a long history of producing critical components in-house when a given part was either not available commercially or the quality of existing offerings was found to be substandard. Early in Tektronix history, components such as precision resistors, transformers, plastic knobs and printed metal instrument front panels were all being built internally.

In 1950 lingering issues with cathode ray tubes, arguably the single most important oscilloscope component at the time, turned much more serious. Tektronix was buying CRTs primarily from RCA and the Allen B. Du Mont Laboratories, but, at the same time these were their principal competitors in the rapidly growing oscilloscope market. New, higher-performing Tektronix scope designs were planned that required performance not available at that time from any CRT provider. Even though Tek was reluctant to telegraph their new-product plans to their closest rivals, they made repeated requests for CRT improvements, mostly to Du Mont, and were turned down.

The difficulty reached a critical level when reject rates for incoming CRT shipments dramatically increased from both vendors. Tektronix was in its fifth year in business and sales were very good and rapidly getting better, but lead times for oscilloscopes were already measured in multiple months. A shortage of CRTs was only to make these lead times worse. RCA and Du Mont were competing with several other companies to produce CRTs and sets for the booming television market. CRTs for the growing, but much-smaller oscilloscope market probably were given a lower priority. In addition, there was evidence Du Mont in particular was intentionally shipping reject CRTs – so called “culls” - to Tektronix. Du Mont historically had been the technology leader in oscilloscopes and they were probably feeling some pressure from Tektronix’ success.

Howard Vollum made a “bet the company” decision for Tektronix to develop a CRT design and manufacturing capability. Imagine a new computer company today deciding to ignore Intel or AMD and choose to make their own microprocessors. Pretty foolhardy. The effort took three years of frustration and trial and error, but the first Tektronix-made CRTs were used in the iconic Type 531 oscilloscopes that introduced the plug-in concept in 1954. And the rest is history.

The CRT operation eventually would flourish for almost forty years, eventually closing in the mid-1990s’. At one point it employed almost one thousand people while producing over one hundred fifty different CRTs in two dedicated buildings (46 & 48) on the Beaverton campus. In 1980 production reached over two hundred thousand tubes per year, likely making it the largest CRT production facility not producing television tubes. As one example, well over a quarter million T465 CRTs were made for use in the high volume portable scopes.

CRT screen size ranged from 2” diagonal to 25” used in the 4016.

Tektronix-made CRTs enabled the groundbreaking performance in many of the company’s leading products, including the T7100 CRT in the showcase that was used in the 7104 oscilloscope, the fastest real-time analog scope every produced. The CRT for the 7104 is probably the most complex tube Tektronix ever made. It incorporates an electron-amplifier, a microchannel plate derived from night-vision technology, in order to support the scope’s groundbreaking bandwidth.

- T51 (early version): a Tektronix replacement for an initially-used DuMont CRT. Starting in the mid-1950s, it was used in the Type 530 and 535 oscilloscopes and a replacement in the 513.

- RCA 3WP1: used in the Type 310, 310A, 315D and 360 oscilloscopes. It was later made at Tektronix as the T310, also on display.

- Three prototype CRTs Bob Anderson used to develop Tektronix' Direct View Storage Tube (DVST) technology (see photo at bottom of page).

- T5640: an early sample obtained from Bob Anderson. A handwritten note on the screen, probably in Bob's handwriting, identifies the split line in the screen, allowing simultaneous examination of two stored traces.

- T519: used in Type 519 scope, capable of DC to 1GHz bandwidth. Employed widely in nuclear weapons testing because its capability of capturing sub-nanosecond pulses.

- T214: DVST version of the smallest CRT Tek made. Used in the Type 214 oscilloscope.

- T2440: used in Model 2465 and several other portable oscilloscopes. Incorporated a revolutionary Tektronix designed meshless quadrupole scan expansion lens.

- T4650: used in the Type 465 oscilloscope and several others, over a quarter of a million of these were produced during its lifetime.

- T6110: Tek's first large (11") graphics DVST, uses the largest ceramic funnel Tek produced. Employed in the 400X monitors and the 4051 and 4052 desktop graphics systems.

- T7100: microchannel plate CRT used in the 7104 1GHz oscilloscope. Probably the most complicated CRT Tektronix made.

- T7612: an electron - bombarded semiconductor sensor used as the digitizer CRT in the 7612D instrument, capable of 200MSamples per second data capture.

- T7630: a storage oscilloscope CRT with three meshes and bistable storage target capable four different storage modes: normal and fast bistable as well as normal and fast variable persistence. The CRT was used in Type 7623 and 7633 oscilloscopes.

- T8250: Avionics color CRT used in the USAF C17 transport.

- T8262: Avionics color CRT (envelope only, no gun) used in the B2 (Stealth) bomber.

- Liquid Crystal Light Valve CRT: prototype projection CRT developed during the 1980's, capable of displaying full HD video. It employed a writing and erase gun used sequentially. This is perhaps the most peculiar ever produced although the design was never productized.

- Scan expansion mesh from the T647 CRT.

- Electron gun from the T2440 CRT.

- Electron gun from the T555 CRT.

- Writing and read guns from the 7912 CRT.

- Samples of deflection plates.

- Mugs and ceramic coaster from the 35th anniversary celebration of the CRT operation.

- The story board on the wall shows photos of early CRT production, profiles of Tektronix CRT engineers and pictures from the shutdown of the CRT facility.

Many of the exhibits came from the CRT Time Capsule. We have some of the most unique CRTs and components ever produced, and all were made at Tektronix.

In 1962 Tek employee Bob Anderson’s invented an elegantly simple storage CRT, touted by Howard Vollum as one of Tektronix’ most significant technical accomplishments. At a time when electronic memory was either prohibitively expense or non-existent, the Anderson CRT allowed an image to be retained on the screen for hours and led the way to an extensive line of industry-leading analog storage oscilloscopes starting with the 564 and the 549.

But Bob’s tube design also led to the creation of storage CRTs suitable for use in computer graphics terminals – a product category Tektronix is credited with creating in the early 1970s. Tektronix proprietary CRT technology resulted in the company being the leading – and for a while, the only – manufacturer of high-resolution computer graphics terminals. It was Tektronix first business unit not based on oscilloscopes. Revenue from the graphics monitor business rivaled that from oscilloscopes for more than a decade. The 611 CRT in the showcase was Tektronix first graphics CRT, used in the 611 and 4002 monitors and the world’s first desktop scientific computer, the 4051 (on the same bench). The 611 was scaled to 19” and 25” where it was used in the 4014 and 4016 monitors, respectively.

Here is a photo of Bob Anderson along with all the prototype CRTs used to develop the first Direct View Storage Tube (DVST) CRT. The three prototype CRTs are in the upper right top shelf of the CRT exhibit.

Our building 13 was a production center for another Tektronix innovation – use of ceramics in the production of CRT funnels. The company developed a ceramics manufacturing capability to produce the ceramic strips that, at a time predating printed circuit boards, Tektronix scopes looked as good inside as out and were simpler to fabricate and service because of the mounting of electronic component on these strips. Ceramic funnels, derived from the ceramic strip technology, permitted the CRT operation to have complete control over the design and manufacture of funnels when companies producing glass CRT funnels were much more focused on making product for the television market. Ceramic funnels also readily enabled the use of flat faceplates and the ability to screen print a graticule – essentially a graph-paper like pattern - on the inside of the faceplate. Storage CRTs also required electrical vacuum feedthroughs that were easier to implement with ceramic funnels. The 611 CRT employed the largest ceramic funnel Tektronix ever made. More information is on our Ceramic Strips and Funnels page.

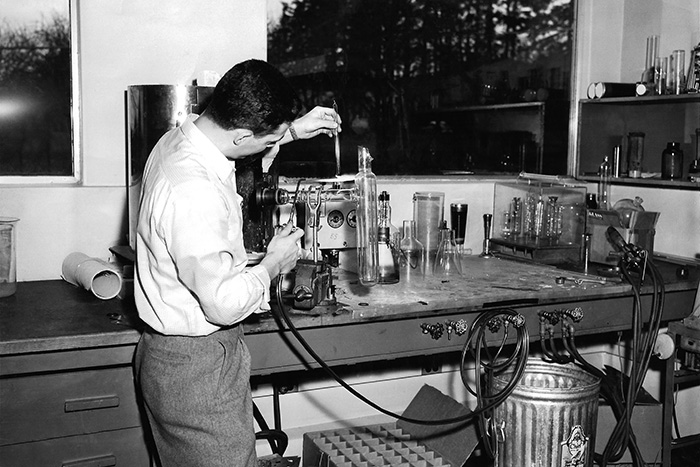

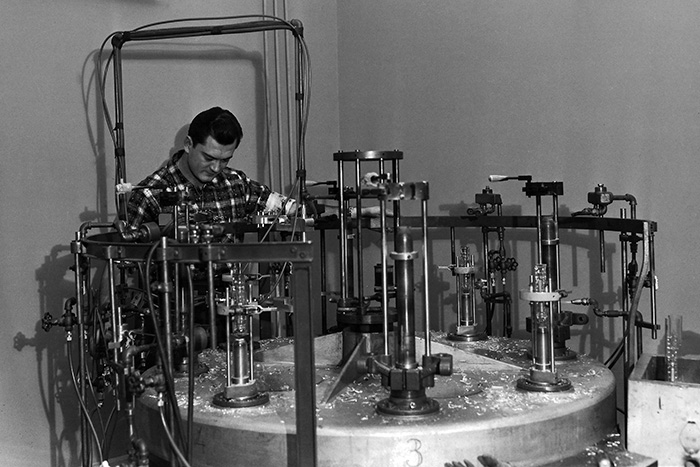

Here are some photos of CRT manufacturing at the Sunset plant.