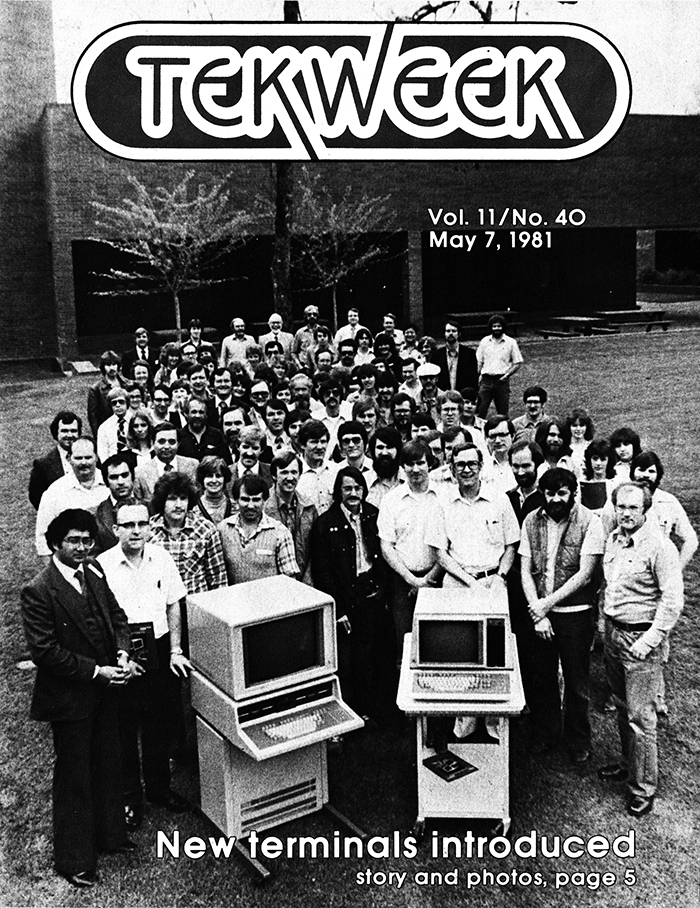

Dave was hired into Tektronix as a college graduate electrical engineer and was given responsibility for the 8080 processor system design for the 4024/4025 products. After a few other minor projects he moved into Program Management. This photo is of the 4112 and 4114 terminal development team when Dave was Program Manager for the Option 41/42 Disk System (Dave is second row center with beard).

Dave later moved into Engineering Management and worked with Dave Cassing and Dave Coreson. In 1989 Dave, Dave, and Dave founded the Network Display Division (NWD) inside of Interactive Technologies Division (ITD) and developed families of X Terminals and Network Display Terminals.

This 1990 film highlights the division's first set of products, the TekXpress family / XP20 / Penguin.

Introducing the TekXpress Family

This April 1994 article describes the concurrent development environment that Dave, Dave, and Dave created to maximize quality, low cost, velocity, and responsiveness in NWD.

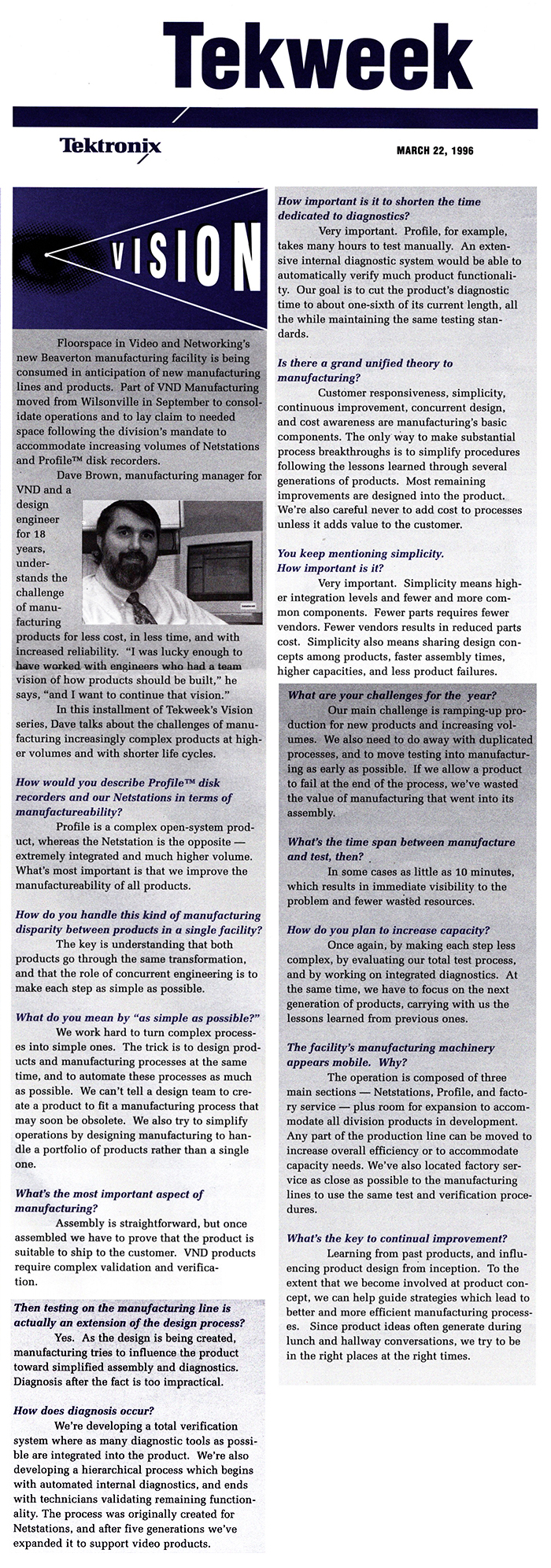

When Dave Coreson moved to corporate, Dave made a career change to manage manufacturing and service for NWD. NWD was merged with Grass Valley Group and the Profile video disk recorder group to form the Video and Networking Division (VND). Dave assumed responsibilities for all Oregon manufacturing. This March 22, 1996 Tekweek article features his vision for VND Manufacturing (the article has been reformatted to fit).

Dave was promoted to Vice President of Worldwide Manufacturing and Factory Service for VND which included Oregon, Grass Valley Group, Newstar (Wisconsin), Lightworks (London), and configuration operations in Heerenveen and Sidney.

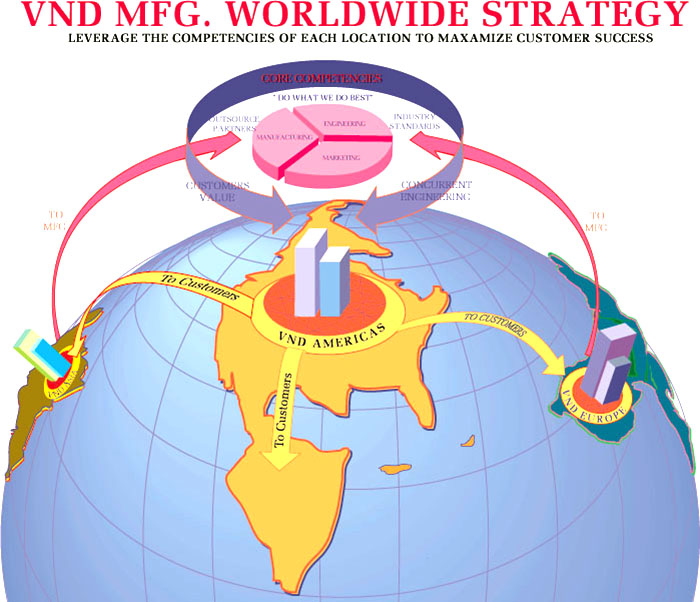

Dave worked with his staff to create simple vision-oriented tools that all employees could understand and relate to. This image is a visual representation of the global manufacturing strategy for VND.

It was reinforced by a Trifold brochure that was used with customers, vendors, and employees. Click on the image to view the PDF.

These brochures proved popular for conveying a consistent message so one was developed for working with the various engineering groups on Design For Manufacturing. Click on the image to view the PDF.

VND created a similar Trifold brochure for the division. Click on the image to view the PDF.

This September 15, 1996 TekWeek article features the ISO 9000 certification of the Oregon manufacturing plant.

In 1999, the decision was made to close VND and disperse the various groups to other entities. The Beaverton production manager made a film of the VND Manufacturing Line Tour and can be viewed on our Video Gallery.

After the divestiture of VND in 1999, Dave moved back to engineering as Vice President of Central Engineering. His responsibilities were broad consisting of functional and infrastructure organizational management, University Relations, Technical Excellence and Engineering Recognition, and Patents and Intellectual Property strategy.

Functional organizations consisted of Advanced Development (e.g. that portion of Tek Labs that was divisionalized), Microelectronics, Mechanical Design, Industrial Design, Customer Focused Design, PCB Design, Power Conversion Design, Documentation, Quality, Reliability, Sustaining Engineering, Model Shop, Team CE Japan, and the Team India Design Center.

Infrastructure organizations consisted of Engineering Tools, Quality Systems, Engineering Information Technology, Product Compliance, Component Engineering, and Product Data Management.

Dave worked with his staff to develop this Central Engineering Trifold that was likewise used with customers, vendors, and employees. Click on the image to view the PDF.

University Relations consisted of partnering with HR to develop and implement the strategy for working with specific key universities. Each university had a campus manager who was responsible for managing all the interactions with the university. Their goal was to create Tektronix mind share on campus and develop working relationships with key faculty to attract the best students. These campus managers were often alumni of the universities and were engineers or managers throughout the company. They were responsible for equipment donations, university research, senior projects, faculty relationships, intern recruitment and employee recruitment. They would also typically participate on university engineering department advisory boards. They would partner with the sales manager for the university to develop a donation plan that would leverage follow-on sales and work towards named laboratories at the university.

The key schools consisted of Oregon State University, Montana State University, The University of Washington, Arizona State University, and Portland State University. An extensions of this program was managed for the University of Texas at Dallas for Tektronix Communications, Sri Jayachamarajendra College of Engineering for Team India, and Tsinghua University and Jiao Tong University for Tek China.

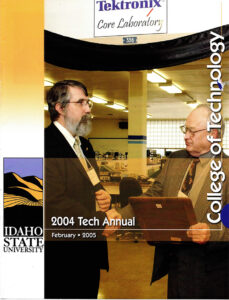

These documents are some PR materials for three named labs. Click on the images to view the PDFs.

Oregon State University Communications and Signal Processing Systems Engineering Design Studio (CASPS)

The University Of Washington Undergraduate Research Laboratory

Although Idaho State University was not a Key School, University Relations would work with other schools as opportunities arose.

This 2008 document has photos of some of the named labs. Click on the image to view the PDF.

The Technical Excellence and Engineering Recognition were separate programs but implemented together. Technical Excellence consisted of a 2 - 3 day Engineering Symposium event with a set of engineering display booths and technical paper presentations. Both were focused on sharing best practices that could be leveraged across the broad organization and geographies. They presented opportunities for technology and design sharing and learning. Click on the image to view the 1st annual Engineering Symposium PDF.

Click on the image to view the Center Stage summary of the 3rd annual Engineering Symposium PDF.

The event culminated with a Technical Recognition Program to formally recognize patent and trade secret recipients. Later, the recognition of Master Inventor was added to recognize those engineers who had achieved 10 patents or trade secrets. The event also recognized outstanding contribution in the form of Engineering Awards.

- The Presidents' Award recognized outstanding contribution by a new college hire. This was typically awarded to more than one recipient.

- The Howard Vollum Award recognized significant contributions throughout a career. This was not necessarily awarded every year.

Four additional awards reinforced the company's operating values of Strategy, Execution, Velocity, and People.

- The Strategy Award recognized an individual who demonstrated the ability to translate an emerging customer need or better understanding of customer needs into new technical solutions.

- The Execution Award recognized an individual whose good planning and execution delivered a solution that mets customer requirements and was sustainable, manufacturable, and profitable.

- The Velocity Award recognized an individual who has driven technical breakthroughs or process improvements that increased the velocity of delivery of a product, service, or technical solution to customers.

- The People Award recognized an individual who strengthened the organization and achieved business result through contributions in developing and mentoring technical employees.

Dave describes in this video from 2000 the introduction of these four awards.

Patent, trade secret, and award recipients can be found on the Engineering Groups, Awards, and Recognition page.

Dave sponsored a number of different events for the employees in his group. These evolved to 1 per quarter and over his 10 year tenure as VP of Central Engineering the group had 44 different events. Before retirement, Dave opened up these events to invite the whole company on the Beaverton Campus. The Summer 2009 event was a music jam. The event team auditioned different employee musicians and groups and the event was a full 90 minutes of music outside in the Howard Vollum memorial plaza. The event team insisted that Dave play, so he did a few songs on the piano.

Dave retired in 2010 and is a charter volunteer at the vintageTEK museum and currently the President. This photo is from The Portland Tribune / Beaverton Valley Times article Tektronix Museum Celebrates Trailblazing Era of Pre-Digital Technology from August 15, 2013. Volunteer Phil Crosby is in the background.